Industry 4.0: everything you need to know about the new age of technology

The new industrial revolution known as Industry 4.0 is revolutionising everyday life in the 21st century. Advances in technology are impacting every industrial segment, transforming production, supply chains and everyday work processes. Industry 4.0 will help to increase efficiency, productivity and competitiveness while enabling innovations to arise in the future. These innovations will fundamentally change the way not only large companies but also small and medium-sized enterprises operate. But what do we call Industry 4.0? What are the principles and technologies involved? We have summarised the most important information!

What is Industry 4.0?

Industry 4.0 is the fourth industrial revolution in modern technological development. This new era is based on digitalisation and automation, where factories are equipped with smart devices and sensors that collect and analyse data to optimise processes. It was Klaus Schwab, founder of the World Economic Forum, who popularised the concept. He believes Industry 4.0 will radically transform our daily lives and working environments.

The Industrial Revolution began in the 1700s when human labour was replaced by machines. The story of Industry 4.0 began with the rapid development of the internet and computing in the early 21st century. Smart technologies and the use of data have made industries more efficient and flexible. This has enabled customised production and immediate response to market needs.

Its importance lies in the fact that it completely redefines the way production and services are delivered. Digitalisation and data-driven decision-making can help companies increase competitiveness, reduce costs and respond more quickly to changing market conditions. Smart factories and integrated systems across networks will eliminate unnecessary waste of resources, ensuring more sustainable operations. Industry 4.0 is therefore not just a technological development, but a new paradigm that will shape the future of our economy and society in the long term.

The principles of Industry 4.0

Digitalisation and automation

One of the basic principles of Industry 4.0 is the convergence of digitalisation and automation. Digital technologies make manufacturing processes not only faster and more efficient but more precise. Thanks to automation, robots and intelligent machines will replace repetitive tasks, increasing productivity and minimising human error.

The role and use of data

In the world of Industry 4.0, data plays a prominent role. Smart sensors and devices continuously collect data that can then be analysed to optimise the manufacturing process. Data-driven decision-making allows companies to make faster and more accurate decisions, further increasing their competitiveness.

Integrated systems and networks

A key principle of Industry 4.0 is the development of integrated systems and networks. Machines that communicate with each other allow production processes to run smoothly and any problems to be identified and solved immediately. This interconnectivity takes industrial production to a new level, where each component works in harmony with the system as a whole.

Industry 4.0 technologies

Industry 4.0 encompasses a wide range of technologies that are becoming increasingly important. Let's get to know the most popular ones.

Artificial intelligence and machine learning

Artificial Intelligence (AI) and machine learning have a fundamental role in developing Industry 4.0. With AI, industries can manage data more efficiently and make predictions that help optimise production processes. With machine learning, the level of automation will continue to increase, so that machines can learn and evolve individually to do their job more accurately and faster.

Internet of Things (IoT)

IoT, or the Internet of Things, is another cornerstone of Industry 4.0. IoT tools enable industries to collect and analyse data in real-time, enabling more efficient and faster decision-making. Integrated systems will further increase automation, and thanks to machine-to-machine communication, production processes can operate with almost no human intervention.

Big Data and analytics solutions

Big Data and analytics solutions are at the heart of Industry 4.0. The global economy generates huge amounts of data, that can provide a significant competitive advantage if properly managed and analysed. This data can help uncover patterns and trends that would have been difficult to spot before, enabling the development of more tailored and effective business strategies.

3D printing and additive manufacturing

3D printing and additive manufacturing are revolutionising the way products are made. These technologies have the potential to produce more complex parts faster and cheaper. Industries can now operate more flexibly and cost-effectively while reducing waste.

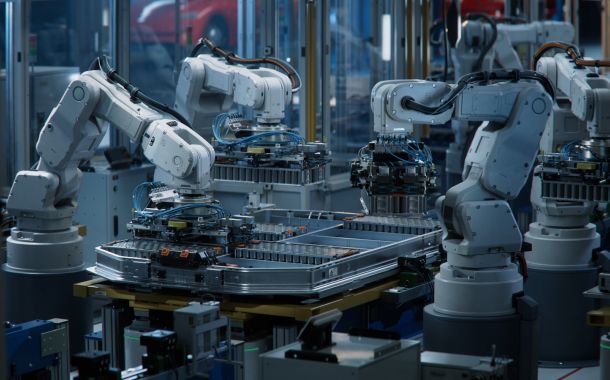

Robotics and automation

Robotics and automation are fundamental building blocks of Industry 4.0. Advanced robots will make production processes faster and more accurate. Automation enables industries to minimise human error and increase productivity. The power and versatility of robots allow them to be confidently deployed in a variety of industries, from manufacturing to logistics.

What are the benefits of Industry 4.0?

One of the biggest benefits of Industry 4.0 is increased efficiency. Using automated systems and artificial intelligence, production processes will become faster and more accurate. This contributes to a significant increase in productivity and minimisation of errors.

Increasing efficiency also has a direct impact on reducing costs. Automated systems reduce labour costs while optimising energy management reduces operating costs.

In Industry 4.0, data becomes an essential part of operations, making data security a priority. Implementing and continuously improving cyber security measures is essential to protect systems against cyber attacks and data theft.

Implementing our Industry 4.0 solutions can pay off for companies. Countless examples show the huge potential of new technologies, here are just a few!

The case of DHL: DHL has implemented Fetch Robotics' AMR (autonomous mobile robots) technology in its distribution centre in the Netherlands, enabling it to efficiently track and move stock. The AMRs move in an automated way and find the most optimal routes in the complex

The case of Team Penske: For teams specialising in motor racing, such as Team Penske, product development is a huge challenge. Thanks to a partnership with Siemens, they have access to advanced simulation and design solutions. For example, the digital twin provides a virtual test bench for engineers to design and develop without touching the vehicle.

The case of GE: GE has embraced augmented reality by deploying AR glasses in its jet engine manufacturing business. This means employees don't have to stop work to plan the next step, as instructions appear in their field of vision. GE says the innovation has boosted worker productivity by 11%.

SynerinSoft is committed to modern technology. We help our customers to benefit from Industry 4.0 with our state-of-the-art solutions. Learn more about our services, and contact us!