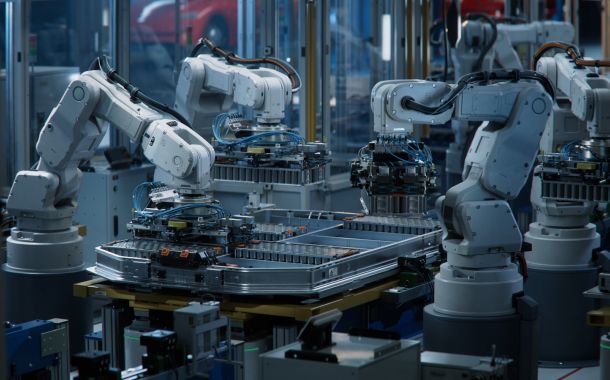

Smart factory: what are smart factories?

Smart factories are at the heart of the modern industrial revolution, that use the latest technologies to make manufacturing processes more efficient. A smart factory's intelligent systems and automated machines use real-time data to improve the quality and speed of production. Based on the concept of Industry 4.0, these smart factories can make the production chain more dynamic, reduce errors and respond to changing needs. Using smart technology solutions, smart factories become more cost-effective, and more environmentally friendly, as they use resources more efficiently. Continuous data analysis helps forecasting, so operators can act proactively before problems arise. Through automation and data-driven decision-making, smart factories are transforming the way industry works, bringing new levels of manufacturing efficiency and flexibility.

Smart Factory concept

The smart factory revolutionises the manufacturing ecosystem, where all processes and machines are tightly interconnected. Integrated systems and machines ensure that every step in production generates real-time data. This continuous flow of data allows operators and engineers to respond quickly to challenges in the manufacturing process, optimising efficiency and reducing errors.

Smart manufacturing combines the physical and digital worlds, opening new horizons for fast and flexible production. Data gives companies instant feedback on all segments of the manufacturing process, enabling them to make changes simultaneously to meet changing market needs. Smart factory solutions aim to make manufacturing more efficient and more sustainable, reflecting modern business requirements.

How does a smart factory work?

The smart factory is the culmination of the modern industrial revolution. It is based on data collection and analysis, which are present at every stage of the production process. Hundreds of sensors continuously collect data on machine status, product quality and environmental conditions. This data is processed in real-time through a connected software network, ensuring smooth operation and rapid response.

The smart factory works on several levels. Let's look at them:

- The first level is about data availability: the aim is to collect available information from all available sources.

- The second level is the contextualisation of data, where the whole production process becomes transparent by putting the data together and interpreting it.

- The third level deals with data activation, where predictions are made using artificial intelligence.

- At the fourth level, action is taken based on data, where machines and systems make automated decisions for continuous improvement and optimisation.

A smart factory can thus create a dynamic, efficient and flexible production environment where data analytics plays a key role in success. Such manufacturing systems increase efficiency and improve production quality, minimising the potential for error and maximising results.

Smart factory technologies

The heart of smart factories lies in technological innovation, specifically sensor uses and the Industrial Internet of Things (IIoT). Production line sensors continuously collect information on machine statuses, movements and environmental factors. Thanks to this data, machines can autonomously detect potential problems and act before they become serious. IIoT allows data to be processed not just locally, but as part of a complex network, ensuring more accurate and faster decision-making throughout the production process.

Using cloud computing and Big Data technologies, the smart factory becomes even more efficient. Cloud services allow manufacturers to expand their resources as needed while minimising infrastructure costs. The flexibility and scalability of these systems ensure that they always deliver the best possible performance, which is essential in the modern manufacturing environment.

A huge amount of data is processed, allowing different prediction and optimisation models, enabling manufacturers to anticipate potential problems, optimise resource use and improve product quality. The transformative power of the data allows for intelligent, adaptive management of production processes, enabling manufacturers to respond quickly to market changes and demands.

The benefits of smart factories

One of the biggest benefits of a smart factory is significant cost reduction. In the digital age, automation replaces manual labour and saves time and money through preventive maintenance. Machines constantly monitor their condition, indicating when intervention is needed, avoiding unplanned downtime and the resulting costs.

Increasing efficiency is also a key focus in the world of the smart factory. Human resources can be optimised through seamless interaction between precision machines, AI-driven decision processes and digital systems. This can make production faster and more accurate while reducing errors and waste

Reducing environmental impact is also a key benefit. The use of sustainable, environmentally friendly materials and technologies brings economic benefits and reduces the burden on the ecosystem in the long term.

Applying smart factory concepts is a technological transformation and an ethical step towards the future. The potential of such factories is huge and the results are noticeably positive for all involved.

Are you choosing innovation? Contact us! SynerinSoft's experienced professionals can help you put technology to work for your company!